Keeping optical transceiver and fiber cable connections clean is an important part of maintaining consistent network performance. Every company that sells fiber optic networking equipment has a page pointing out the importance and tutorials on cleaning your transceiver and cable end connectors. There are several links to these at the end of this document. If you have a connection that started dropping packets, has link flapping, or other unstable link issues, your first step in troubleshooting this should always be to clean both the transceiver connector and fiber cable connectors on both ends of the link.

Transceivers and fiber cables should always be plugged in, either into each other or have dust caps on them. Clean fiber optic components are an absolute requirement for quality connections. Any contamination in a fiber connection can cause failure of the component or the whole system. A microscopic dust particle that partially or completely blocks the core generates strong back reflections, which can cause instability in the laser system.

Please contact your GigaTech sales rep if you need cleaning supplies.

Dust particles trapped between two fiber faces can scratch the glass surfaces. Even if a particle is only situated on the cladding or the edge of the endface, it can cause an air gap or misalignment between the fiber cores which significantly degrades the optical signal.

- A 1-micrometer dust particle on a single-mode core can block up to 1% of the light (a 0.05dB loss).

- A 9-micrometer speck is still too small to see without a microscope, but it can completely block the fiber core. These contaminants can be more difficult to remove than dust particles.

By comparison, a typical human hair is 50 to 75 micrometers in diameter, as much as eight times larger. So, even though dust might not be visible, it is still present in the air and can deposit onto the connector. In addition to dust, other types of contamination must also be cleaned off the endface. Such materials include:

- Oils, frequently from human hands

- Film residues, condensed from vapors in the air

- Powdery coatings, left after water or other solvents evaporate away

These contaminants can be more difficult to remove than dust particles and can also cause damage to equipment if not removed.

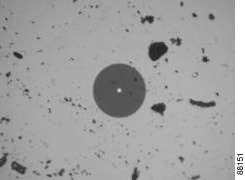

After a few years, it is highly likely the transceiver needs to be cleaned. Below is an image of the end of a fiber cable that has dust all over it. That tiny white dot in the middle is the actual fiber that the light needs to pass through. If this is covered by anything the optic will not work. When a dirty cable is connected to the transceiver it will pass along any dust or oils to the transmit and receive ends of the transceiver.

It is relatively easy to clean the connectors if you follow all of these steps:

1. Open the dust cover or remove the dust plug from the module.

2. Use a non-abrasive cleaner (canned air) to remove any dirt or debris.

3. Insert a lint-free cleaning stick of the appropriate size (2.5 mm or 1.25 mm) and turn clockwise. Dry cleaning is recommended. Do not use alcohol-based cleaning sticks!

4. Remove the cleaning stick, close the dust cover or reinsert the module’s dust plug. Always keep the dust cover or dust plug inserted in the module when not in use.

5. Always make sure that the connector that will be plugged into the module is also clean before connecting it to the module—to prevent cross-contamination.

6. This procedure should be followed when connecting or disconnecting fiber to or from the module.

Cable and Transceiver Cleaning Sources:

Cisco, Juniper, Arista, Dell, HP, CommScope, Avaya